Model No.: Anodizing Battery Box

Brand: DUNGANLI

Place Of Origin: China

Service: Mold design, extrusion, forging, heat treatment, precision cutting, spraying, sandblasting, anodizing, CNC,welding

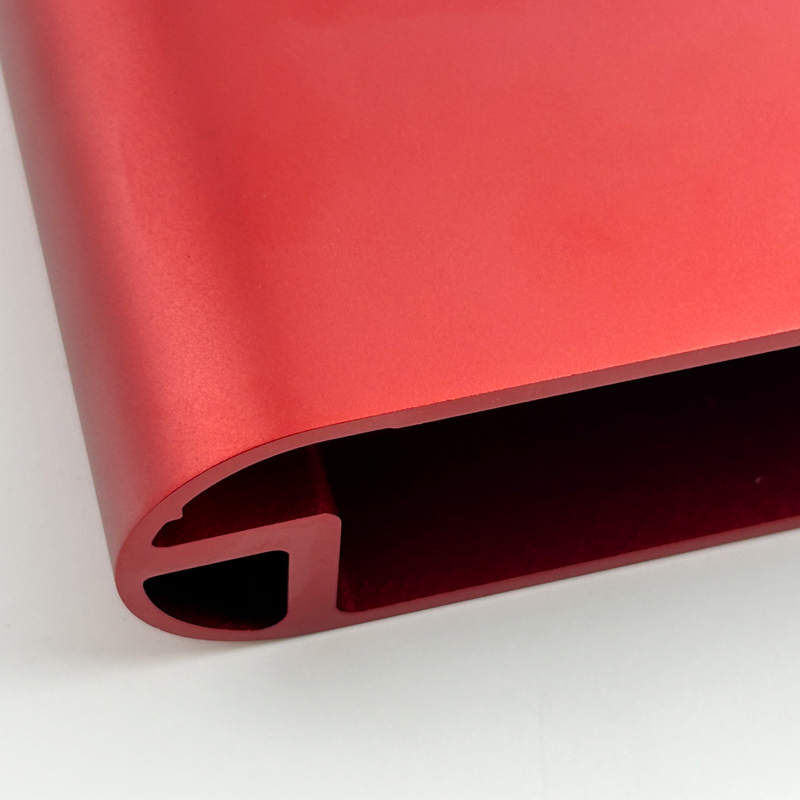

Product Name: Anodizing Battery Box Powerbank Aluminum Shell

Packaging: Film, pearl cotton, cartons, wooden cases

Transportation: Ocean,Land,Air,Express

Supply Ability: 500000PCS/M

Port: Foshan,Guangzhou,Shenzhen

OEM Aluminum Profile Enclosures – Precision CNC Machined, Customizable, and Durable

Discover premium aluminum enclosures engineered for industrial-grade performance and aesthetic versatility. These Custom Aluminum Shell solutions are crafted from high-strength 6000 series alloys—such as 6061, 6063, 6082, and 7005—to deliver superior corrosion resistance, lightweight durability, and long-term reliability across demanding environments. Whether you're designing a power bank housing, battery box enclosure, or precision component for aerospace, automotive, or electronics applications, our OEM aluminum profiles provide the flexibility to meet exacting technical and visual standards.

Key Features:

Our aluminum profile enclosures support advanced manufacturing techniques including CNC machining, micro milling, laser engraving, silkscreen printing, and custom-cutting for unique branding needs. Surface treatments such as hard anodic oxidation, chrome plating, nickel plating, and polishing enhance both functionality and appearance, making them ideal for outdoor, marine, medical, lighting, and telecommunications equipment. Wall thickness tolerance is maintained within ±0.05mm, ensuring precise fitment in complex assemblies.

These enclosures serve diverse industries—from construction machinery and agricultural equipment to home appliances, electric vehicles, and industrial automation systems. Their robust structure makes them suitable for harsh conditions while maintaining sleek aesthetics for consumer-facing products. The ability to integrate custom logos, cut-outs, and branded packaging adds value for B2B clients seeking differentiated product offerings.

Customers consistently praise the balance between affordability and precision engineering. Many highlight how the customizable options—from material selection to finish type—allowed them to reduce prototyping costs and streamline supply chain operations. Others note the professional finish and consistent quality that enabled their products to stand out in competitive markets.

Frequently Asked Questions:

Can I request a sample before bulk production? Yes, we offer small batch samples for approval prior to full-scale manufacturing.

What if my design requires non-standard dimensions or special coatings? Our team supports bespoke designs using CAD files or physical prototypes, with tailored solutions for surface treatment, tolerances, and assembly methods.

Do these enclosures comply with international safety regulations? Absolutely—they meet ISO 9001:2008 standards and are suitable for use in regulated sectors such as medical devices, electrical enclosures, and transportation components.

Whether you need a rugged battery box for energy storage systems or a sleek aluminum shell for portable electronics, this OEM solution delivers unmatched adaptability, quality, and speed—making it the go-to choice for global manufacturers seeking reliable, scalable aluminum enclosures.

Product Categories : Aluminum Precision Machining