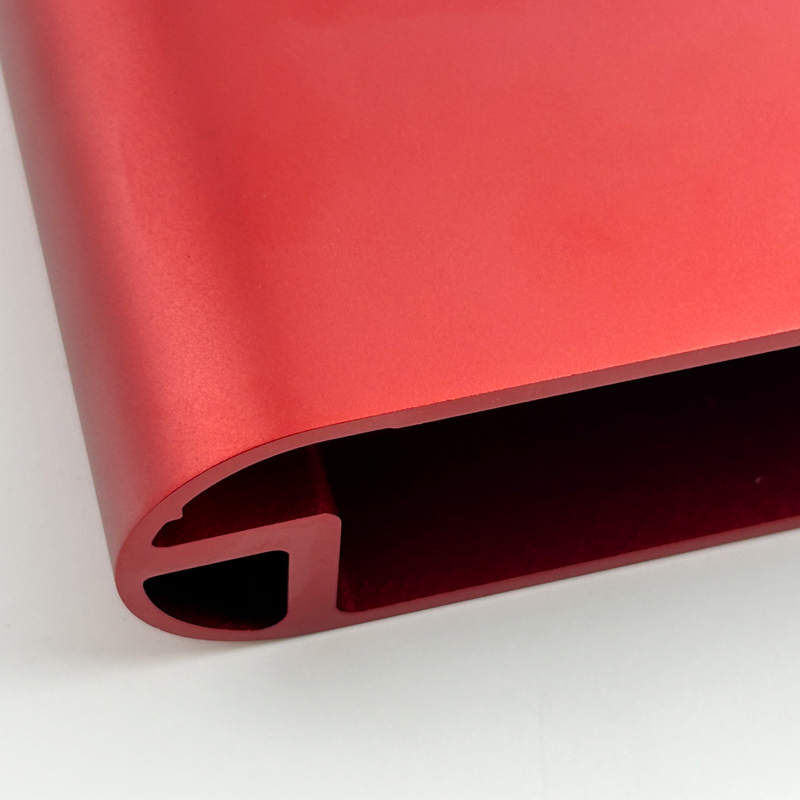

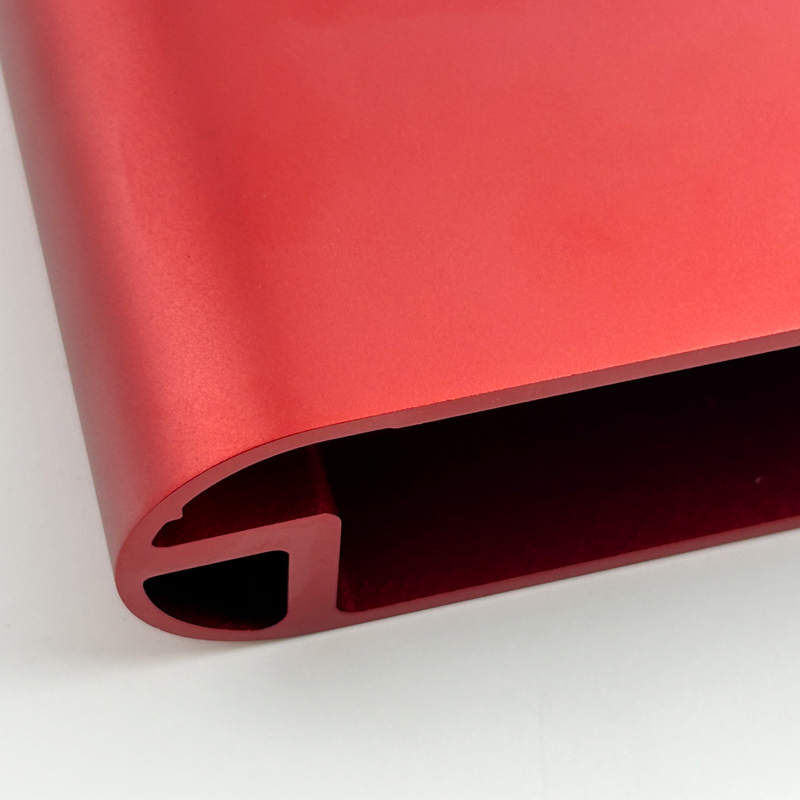

Identification methods for aluminum alloy shell profiles

Aluminum alloy profiles are widely used non-ferrous metal structural materials in this industry and have been extensively applied in aviation, aerospace, automobiles, mechanical manufacturing, shipbuilding, construction, decoration and chemical industries. In recent years, with the rapid development of science and technology and industrial economy, the demand for aluminum alloy shells has been constantly increasing, and the research on the weldability of aluminum alloys has also become increasingly in-depth.

Now, we mainly introduce several simple identification methods for aluminum alloy profiles:

1. Marking inspection: Check whether the aluminum profiles and packaging are marked with the product standard code and production license number.

2. Surface quality: The surface of aluminum should be thoroughly cleaned. It is not allowed to have defects such as cracks, peeling, corrosion, and bubbles, nor should it have defects such as corrosion spots, electric burns, black spots, and peeling of the oxide film.

3. Oxide film thickness: The oxide film on aluminum profiles is formed during the anodizing process and serves both protective and decorative purposes. It can be tested with a thickness gauge.

4. Sealing quality: After anodizing, there will still be many voids on the surface of the aluminum profiles. If not closed or closed, the corrosion resistance of the aluminium profiles will be greatly reduced. Common methods for quality inspection of sealing holes include acid leaching, admittance and phosphorous acid. The acid immersion method is usually used in the inspection. The surface of the aluminium profiles should be wiped clean with acetone to remove oil and dust. Drop 50% nitric acid by volume onto the surface and gently scrub. One minute later, wash off the nitric acid with water and then dry it. Drop a drop of medical purple medicine on the surface. One minute later, wipe off the purple syrup and thoroughly clean the surface, observing any remaining marks. Aluminum profiles with poor sealing performance will leave obvious marks. The heavier the mark is, the worse the quality of the sealing hole will be.

5. Corrosion resistance: This indicator will affect the service life of aluminum profiles. Corrosion resistance tests include copper-accelerated acetic acid salt spray tests and alkali drop tests. This test is used to determine the test time of the tested aluminum alloy to varying degrees, in order to analyze its service life during normal use. The higher the corrosion resistance, the better the mechanical performance data and the longer the service life.

This company is a high-tech enterprise specializing in aluminum processing and services. The company now has a professional technical and management team of [sensitive word], as well as first-class aluminum processing equipment and production testing equipment, and strictly implements the ISO9001:2008 quality management system. This company specializes in the production of aluminum casings, aluminum casing manufacturers, aluminum casing processing, Shenzhen aluminum casing processing, aluminum casing processing, aluminum alloy casings, aluminum casings, power aluminum casings, power bank casings, power bank aluminum casings as well as heat sinks, chassis Hairpins and various industrial profiles have won over many well-known domestic and foreign enterprises (such as SONY, Huawei, Nokia, Lenovo, BYD, 020-6, etc.). The company is striving to become a trusted aluminum manufacturing service provider.